When Every Call Counts in Manufacturing

In manufacturing, one unanswered call can mean more than a frustrated customer. It can signal a delayed shipment, a stalled production line, or even a breach of contract. High abandonment rates and missed service level agreements (SLAs) carry financial consequences that go far beyond the contact center. They can trigger penalties, jeopardize renewals, and weaken trust with key partners.

AI is helping manufacturers flip the script. By predicting demand, surfacing insights, and guiding agents in real time, AI-driven tools give teams the ability to keep abandonment down and SLA performance up. Here are six practical ways it makes a difference.

1. Forecasting Demand with AI

Manufacturing contact centers often face spikes in demand tied to seasonal orders, product recalls, or maintenance cycles. Without preparation, these surges overwhelm queues and push abandonment rates higher.

AI can analyze historical data to forecast call volumes and help leaders prepare staffing before the surge arrives. Instead of reacting to an overloaded switchboard, teams can scale support in advance. With Xima’s advanced reporting, manufacturers can spot the patterns behind peak demand and plan resources with confidence.

2. Keeping Customers in the Queue (Without Keeping Them Waiting)

Few things frustrate a supplier or distributor more than being stuck on hold. When minutes tick by, abandonment becomes inevitable—and in manufacturing, an abandoned call can mean a missed order or a delayed part that cascades into lost production time.

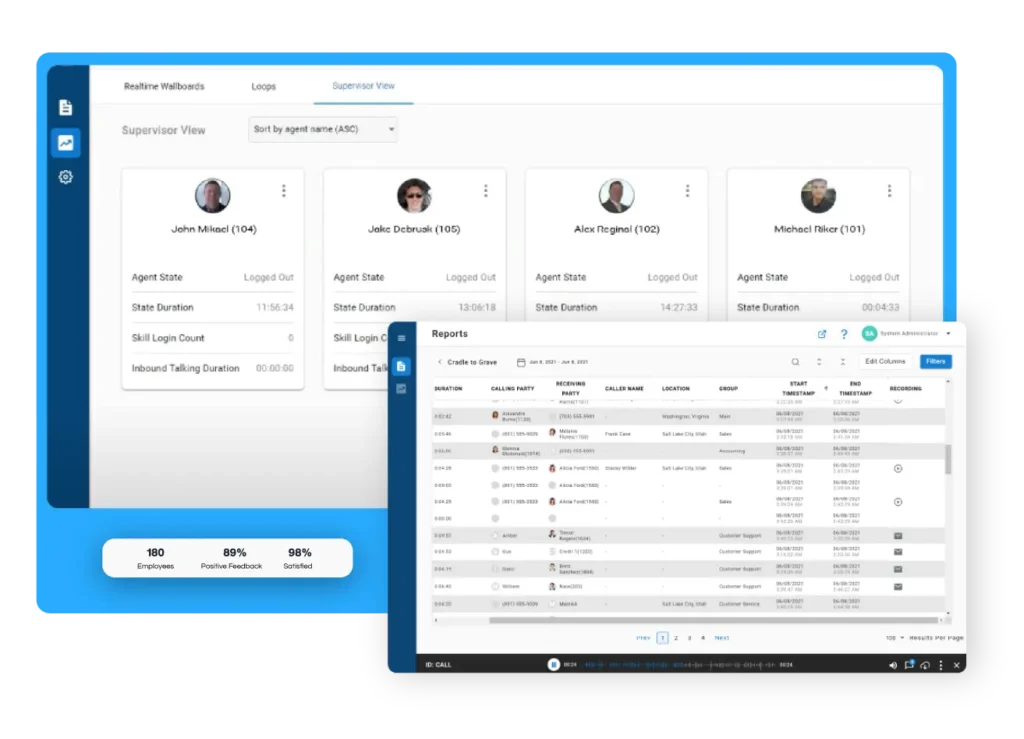

AI-enabled callback and smarter queue management ease that pain. Instead of waiting, callers can hold their place in line and receive a return call when an agent is free. It is a simple way to cut abandonment while keeping customers engaged. With queue callback and cradle-to-grave tracking, Xima makes it easy for manufacturers to keep customers connected without stretching agents beyond capacity.

3. Real-Time SLA Dashboards

Meeting SLAs requires more than end-of-month reporting. In manufacturing, a missed SLA might mean contractual penalties or open the door to competitors at renewal time. Supervisors need to know the moment a metric is at risk.

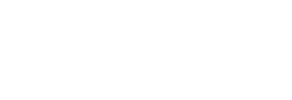

AI-powered dashboards provide that visibility, highlighting queues or call types in danger of breaching SLA targets. Leaders can adjust staffing, reprioritize work, or re-route calls in real time. Xima’s real-time wallboards give manufacturing teams the live insights they need to keep commitments on track.

4. Guided Workflows for Complex Manufacturing Issues

Not every call is a simple status update. In manufacturing, conversations often involve parts availability, machine downtime, or logistics delays. Each situation comes with compliance requirements and technical details that can extend call times and put SLA promises at risk.

AI-driven workflows help agents navigate these scenarios step by step. By surfacing the right process at the right moment, workflows reduce errors and keep calls moving—protecting both the SLA and the customer relationship.

5. Unified Data Access for Faster Answers

A supplier should not have to repeat an order number three times before getting help. Yet disconnected systems often force agents to scramble for the right information while the customer waits. That wasted time does not just frustrate the caller, it threatens SLA compliance and increases the chance of a non-renewal.

AI solves this by unifying data and presenting account history, past interactions, and order details in one view. Agents resolve issues without hunting across systems, and customers feel heard. With Xima’s CRM integration, manufacturers can connect their contact center to existing systems and reduce the friction that drives abandonment.

6. Continuous Improvement Through Analytics

Call abandonment and SLA compliance are not just day-to-day measures; they are leading indicators of systemic issues. If left unchecked, they signal deeper problems that can erode partner confidence over time.

AI-powered analytics turn these metrics into a feedback loop for improvement. Speech analytics can uncover recurring complaints, highlight moments where agents get stuck, and reveal patterns that training alone will not fix. By closing the loop, manufacturers build a support system that learns and improves over time.

With Xima’s AI-powered contact center tools, leaders do not just see the numbers, they understand what drives them—and how to act before contracts or customer relationships are at risk.

Closing Thought

Manufacturers pride themselves on precision and reliability on the factory floor. The same standards should apply to the contact center.

AI-driven insights help reduce call abandonment, keep SLA promises, and prevent the costly ripple effects of missed commitments. When every call counts, AI makes the difference between stalled production and satisfied partners—and between a contract at risk and a contract renewed.